Working out how much an ethical & sustainable product should actually financially cost is more complicated than it should be. It’s also not fun. As a society we have been conditioned to cheap products. Five dollar t-shirts. Ten pound jeans. We baulk at higher numbers. But there are also people buying thousand dollar goods that are made by children. From cheap and terrible materials. That we overvalue simply because of good branding and status. Or we spend a couple of hundred dollars because we want to feel a bit better about our choices but we didn’t do the research to figure it out (also difficult in a world that requires us to constantly be working to survive). We’re a complicated bunch.

Determining what is even part of an ethical product is difficult. There are intangible costs like good working environments for example. Renovating the local organization we work with cost tens of thousands of dollars and was self-funded (the privilege of temporary debt helps too). Pricing that into our products would have meant they were accessible only to the richest which doesn’t make sense in this movement. We’re also not taking into account any environmental costs which every product has no matter how ethically and sustainably it was created. As a world we have little idea how to deal with costs beyond the monetary. With the experience we’ve had in this, let’s try to understand the true financial cost of an ethical product, some basic tenants that should be included, and why greenwashed products from big companies have different standards and can do this far easier.

Effective Hourly Rate

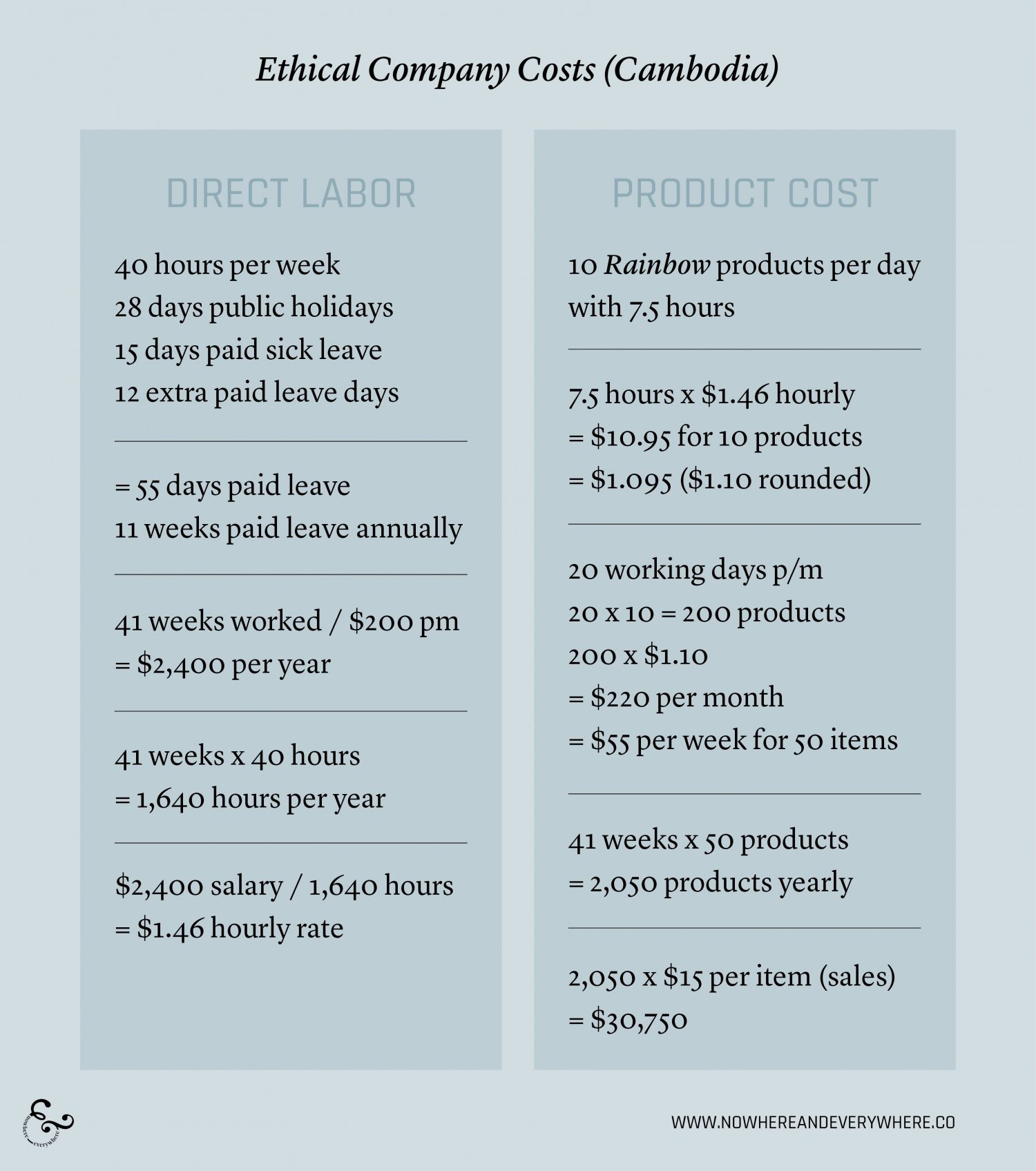

Let’s start by setting $200usd as an arbitrary monthly salary figure for a staff member making the goods so we can make an equal comparison between scenarios.

We’ll run with what we know, but this can be used for other small businesses doing their own work and production too. At our production centre in Cambodia we largely work 7.5 hour days, 5 days a week on average. Sometimes we work different hours and on weekends when the power is off a lot due to the drought (in which case staff spend more time at home and there are more breaks during the week when nothing can be done). Let’s average it out to 40 hours per week (with a 2 hour lunch break).

As part of direct labor, we also have:

- 28 days official paid holiday (Cambodia seriously has the most public holidays in the world!)

- 15 days paid sick leave (the NGO has set this standard which we followed)

- 12 extra days paid additional leave (Cambodians enjoy taking days off before and after major holidays and it is expected these are paid in our organization and area)

That totals to 55 days (11 working weeks) paid leave per year at our centre (for most of us in industrialized nations, this is a huge amount and not currently anywhere near feasible but we would love if the whole world could of course have this and developing countries have better pay, increased living standards etc).

This doesn’t include parental leave for which our staff are covered by insurance we pay for three months or anything similar.

In a 52 week year therefore, 41 weeks are actually worked, at an average of 40 hours per week. At $200 per month that would result in $2,400 a year with an hourly rate of $1.46.

Direct Product Labor

That means if we can make 10 of product Rainbow per day with one worker (7.5 hours – any extra little time for the working week is also used for organizing, cleaning up, laughing at videos etc – normal office things!), it costs us $1.10 per Rainbow item. That’s an arbitrary number for our calculation sake here; once you cut all the fabrics, iron them, sew, create the drawstrings (we do this ourselves with the hemp) etc you’d probably come to just a little more than this per day on average.

500 of that item would equal $550 and 50 working days. Thus in two calendar months we would make approx 400 Rainbow products. Each month therefore we could make 200 products with one dedicated worker (or 50 products a week). With an effective working year of 41 weeks, and sold at $15, at the end of the year we have the ability to sell 2,050 Rainbow products for $30,750.

Sewing at our little centre in rural Cambodia. We partnered up with a local NGO we’ve worked with for the best part of a decade to transform it into a happier, positive, lighter & bigger workspace and create a space that supported community projects in the region. It’s super chilled out and relaxed here and there’s usually a bunch of kids hanging about between school sessions (particularly for the fans!).

Mass Produced Items

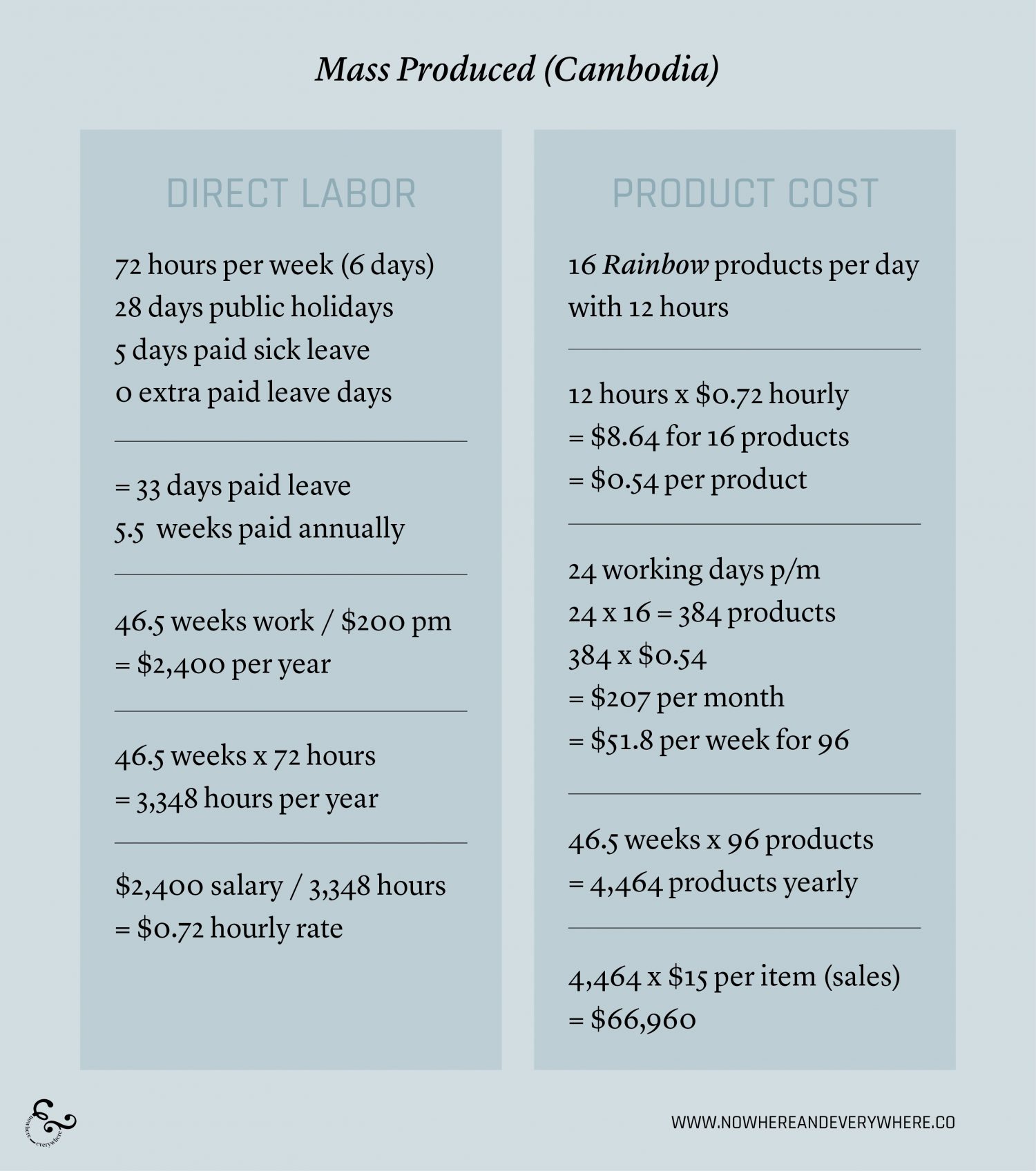

For a manufacturing company, a small business ordering from China online, or a company working with a garment / production factory requesting their own items, they usually do quotas when ordering. For example, the business will place an order for 1,000 pieces of Rainbow product. Workers are kept in the factories to meet those orders no matter how long they take. Usually they work 12 hours a day for 6 or 7 days per week. Let’s run with 6 to err on the lower side for fairness. That makes for a 72 hour working week along with:

- 28 days paid official holiday (as per Cambodia for comparison sake to our product – other countries have far less)

- No additional leave is paid (not required by law)

- 5 days paid sick leave (allowing for this where it does happen, in many places this is unpaid)

This totals 33 days paid leave per year and with 6 day working weeks totals just over 5 weeks a year. In a 52 week year, 46.5 weeks are worked at 72 hours per week making for a monthly salary of $2,400 a year (the same as the above example) but an hourly rate of $0.72.

That means if they work at the same rate as our staff, they can make 16 Rainbow items per day with one worker of 12 hours and it costs them $0.54 for that same item.

In one calendar month they can make 384 of the product (nearly double the ethical business) at a cheaper price. Sold at $15 for example that’s $15,000 in income. At the end of the year they have the ability to sell 4,464 of that product for $66,960, more than double the example above.

Total Product Costs

That’s just the workers making the products and the sale of those potential products. From there we can get into fabric costs and other sustainable options to find the cost price of the product. We make our own coconut buttons to use the waste husks we collect for the bowls that aren’t the right shape and have a natural button that composts. We also provide a spare button for every button on an item so items can last longer and maintain their original look and style (important for us as consumers to keep goods going).

Let’s say for this product we’re using 100% hemp, sustainably grown and spun, which we try and do as much as anywhere close to feasible. It’s nearly $30usd per metre – far more expensive than cotton – grown close by and ethically (read this, and this to learn why hemp, not cotton). For our $15 product, let’s say it’s a total fabric size of 40cm x 50cm required to make this (that’s the size of our medium produce bags). Therefore we get:

Ethical & sustainable

$0.82 workers wage

$0.12 insurance for the worker on this product

$2.05 for 100% hemp

$0.15 contingency funds for the centre

$0.18 1 coconut button

$0.08 for sewing thread

$0.30 centre bills

$0.07 shipping to us

$0.25 product packaging when sending out with custom recyclable packaging

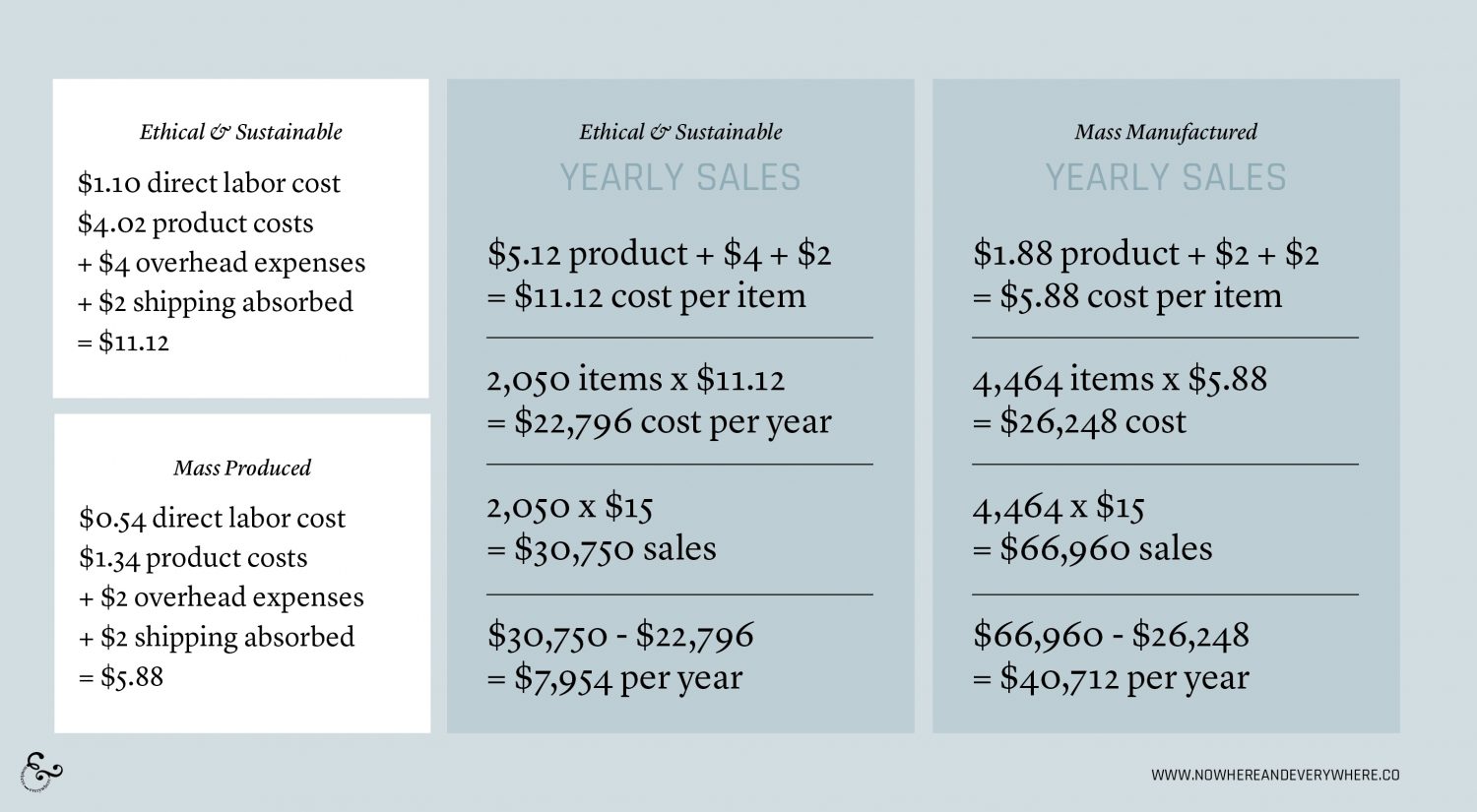

Total = $4.02

Note: this does not include any of our own salaries (which are needed to get the product made in the first place, do marketing, keep socials going let alone do all our research and education work etc), business costs to cover all this (apps & software, studio rent, accountants, bills, website servers, domains, etc), marketing costs (i.e. ads or paying for a collaboration), sourcing & development, trips to run training sessions, and more.

= $4 (approximate addition to each product item with only a tiny amount of this covered for low minimum-wage developed country salaries)

Total = $8.02 cost per item

A note on shipping:

We as consumers also expect free shipping these days. We as a small enterprise obviously can’t afford to provide this free for everything but we still need to absorb the cost of a small portion of our high shipping expenses into our product as we lose money on it.

The actual cost

Finally note that these cost equations include no upgrades to the centre, no coverage for replacing or adding new primary furniture & machines, no water & snacks that are provided etc. It does cover emergencies (that happen more frequently then we’d like in this climate changed ravaged area!) and supplies that we need such as sewing chalk, new scissors etc.

If we absorb a small shipping amount of $2 (an item like this would cost us $6 – $15 ship depending on location) in our product cost would equal approximately $11.12.

To sell it at $15 we would make $4 – and that isn’t any profit due to all the expenses this didn’t cover. This product would just pay for direct labor staff, materials and running centre costs. Ideally, we would price this product for retail at about $30. If we wished to wholesale it, we would drop this margin as tightly as we could (marketing costs reduce, higher value orders etc) and it would mean the product retail value would have to be closer to $50. Normally a wholesale price is 100% from your cost price to fully cover overheads and still generate some profit and then retail is another doubling of that price so shops can cover all their expenses, rents, wages, marketing etc.

This product price covers everyone from the sustainable farmers including their manager to craft the handspun fabric, to the ethical labor of creating it to the team it takes to source fabrics, design the items, market them, run a website and the million hours that make up a business week.

So our slightly profitable product price should be at least $30usd.

We’re not working for profit on these items and we just want these products to be able to provide for decent jobs in our little area and allow us to train local people to run projects and so we can run environment education sessions. Essentially we do a huge amount of hours for free (well, the team outside of myself gets paid for their time still by us doing additional other projects) so that we can ensure others have more opportunity than it existed (it’s definitely not perfect). This is another way of spending your privilege.

You can imagine then what it would look like if we were; it simply wouldn’t be feasible in the current market to have a sustainable material like hemp, thoughtful waste management like handmade coconut buttons from local waste, using all scraps for labels (which factories can’t do) and ethical labor. The market wouldn’t pay for it when all the competition is priced at $10 – $15.

There are clearly two levers to pull here; fabric costs and wages. In industrialized countries, you’d be paying significant amount more for the direct labor cost if say someone in the UK, Australia or America is making it. It would instantly shoot up which often results therefore in inferior materials being used to try and somewhat offset this cost (plastic nylon & polyester). Examining this gives good insight of just how difficult it would be to run a profitable small business that has both ethical labor in-house in a developed country and truly sustainable materials.

Mass Produced Product Price (Arguably Unethical & Unsustainable)

For the big company, or the small business sourcing most of their goods from a developing country factory, it’s a different story. With that same size of material required, the product cost would be:

$0.53 workers wage

$0.12 insurance for the worker on this product

$0.35 for synthetic fabric or cotton (the bigger the amount that can be purchased the cheaper this gets too – organic cotton is more expensive but much cheaper than sustainable hemp or linen especially when it’s grown in India or a developing country)

$0.02 one plastic button

$0.07 shipping to company destination (their shipping may be less due to the huge amounts but for small business quantities it would be similar so we’ll keep it the same here)

$0.25 product packaging with custom recyclable packaging (usually they use polybags and plastic from factories but let’s say they’re really trying on packaging too)

Total = $1.34

This does not include the selling company salaries, marketing costs and the likes either. It’s hard to work out what these would be. For a huge conglomerate these might be a lot more or a lot smaller due to scale of economies. Or for marketing they’re way bigger, with way bigger returns (the more you invest, the more you get out of it). For a smaller business who orders from China or India, this might be the same. For comparison sake, let’s say it’s the same rate as our $4 per item, so given they’re able to produce twice as much, that would be $2 additional per item (this would likely include the factory profit overhead which would like also be scraped from a number of other higher-end calculations we’ve included here for ease).

Including the same small shipping absorption of $2.00 (most big corporates would have this significantly reduced to a few cents only per item due to volume and none at all for retail outlets that don’t sell online), the product cost is $5.88. To sell it at $15 they would therefore make $9 compared to our $4. Or for a conglomerate, $11 to our $4. Over a large amount that quickly scales up to a massive difference.

Total = $5.88 cost per item

Profit & Sales

Remember we have the ability to make 2,050 by one person, for this one product, in a year which would cost us $22,796 with a profit of $7,954 (loose word as it doesn’t cover all the expenses). The big company manufacturing in India or Cambodia or Vietnam, or the small business sourcing from China, could make nearly fives times the profit for nearly the same expense in a year with a windfall of $40,712 a massive $33k difference.

It’s an uneven game and it’s difficult to drill down this far into each product item. Even when a business is claiming to be ethical and eco-friendly, most of us don’t know the specifics of the work conditions and product costs like this. An hourly rate is the absolute surface of something – it says nothing of how many hours are actually worked, what the conditions are and what it represents in a local context. We wanted to highlight this as an example of how true ethical labor can really influence a product price along with sustainable materials. The combination of both sees our products be priced far higher.

We don’t have the answer to this other than that consumer behavior and expectations need recalibration. We need to buy a lot less (reduce, reduce, reduce) but buy a lot better quality. We need to make certain standards accessible and implemented in every country in the world and then tackle systemic inequality and price affordability more too. We need governments to support sustainable and regenerative production of materials like hemp. We need strong funding support within these industries and more public & shareholder demand for transparency. We need to ask many more questions of companies if they’re not transparent on their site and socials when you’re looking for the information. We need to understand how products are constructed and what materials are the best for our environment overall. We could do with quite a few ongoing classes at school throughout the years to educate kids who become adults not having to unlearn everything they were taught or accustomed to.

This is also definitely an area the law can step into. Free markets and capitalism are all good and well but when they consistently exploit people and create this form of required labor and environmental destruction to meet demand (and economic growth) something has gone wrong and needs policy adjustments or regulating. A lot businesses could be served through significantly more government support to ensure sustainable and slower production (we subsidize fossil fuels to the tune of trillions after all) and this would create avenues for increased accessibility too.

Buy less, buy better. Question businesses who lack transparency. Don’t buy into greenwashing. Support ethical labor and sustainable materials when you need something or are gifting.